A student will design a robust, learning-based drift prediction and control model for ASML TwinScan lithography systems that integrates physics and data-driven methods to handle non-uniform measurements, time-varying uncertainties, and diverse drift dynamics while outperforming the current nominal controller.

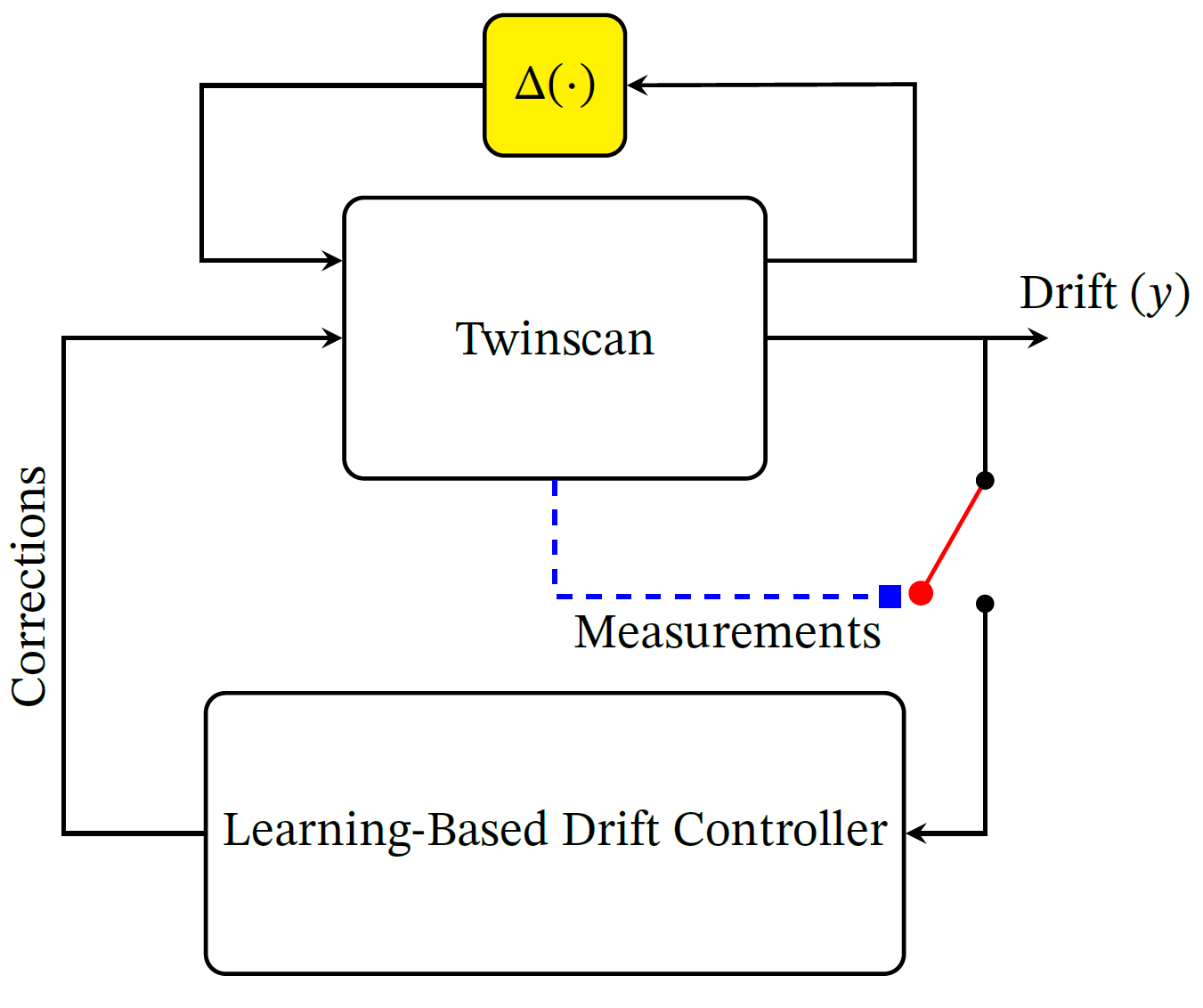

State-of-the-art static event-based controller. Figure courtesy of ASML.

Project positioning

This project is sponsored by ASML. You will be working in the Bayesian Intelligent Autonomous Systems lab (BIASlab) at TU Eindhoven. BIASlab develops probabilistic models and inference algorithms for signal processing and control problems.

Supervision

- Weekly progress meetings with Raaja Ganapathy Subramanian.

- Periodic progress meetings with BIASlab researchers.

- The student should prepare for meetings in advance, e.g. with slides or notebooks.

Student task description

TwinScan lithography systems are used at a very high-speed to produce integrated circuits which requires sub-nanometer accuracy and precision. However, during the operation the system drifts—after all its just a combination of metals and materials, causing a negative impact on both the (sub-)nanometer-scale positioning and getting plauged by different classes of uncertainties (like changes in boundary condition, operation sequence induced errors, etc). The current drift control is nothing more than a nominal exponential moving average. Clearly, this poses several challenging control problems mainly because

- the measurements are not ideal. Thus being prone to

- measurement noises which are of time-varying nature (i.e., colored).

- uncertainties creeping the performance.

- unmodelled physics impacting the prediction accuracies.

- these drifts often possesses different dynamical nature over time per product per machine. So using a nominal controller is close to impossible/non-optimal. Further to control lag, we measure very frequently, every day to 3-days which is a cost for customer.

In this project, the student will use a combination of physics and data-based prediction techniques to design a dynamical learning-based prediction model that can provide robust performance.

Concrete tasks

The robust controller needs to have several intrinsic characteristics:

- Deal with non-uniform measurements in order to update the predictor’s (internal) states.

- Should be a global controller to deal with different classes of drifts while guaranteeing robust performance

- Possesses smart decision making capability by learning from past in order to deal with sequence induced uncertainties

The performance, advantages and disadvantages needs to be compared with benchmark and real-measurement data, and against the current state-of-the-art controller. Finally, the student is expected to finish the internship with a concise report/manuscript and talk(s) to be held at ASML and the university.

Timeline

8-10 Months